Needle-punched non-woven fabric can serve as an insulating layer within a mattress due to its compos... - 2023-09-01

Needle-punched non-woven fabric can serve as an insulating layer within a mattress due to its compos... - 2023-09-01

Needle-punched non-woven fabric is widely used in the manufacturing of mattresses due to its various... - 2023-08-24

Industry Knowledge

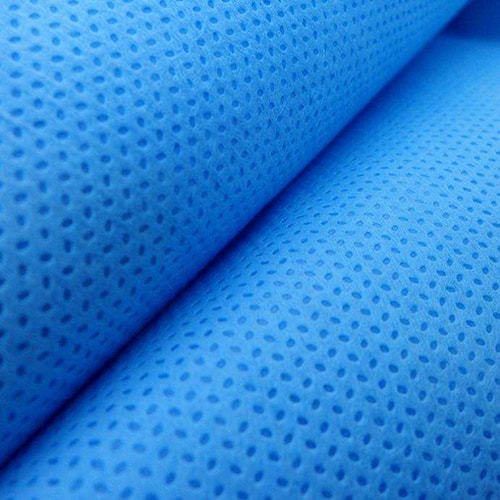

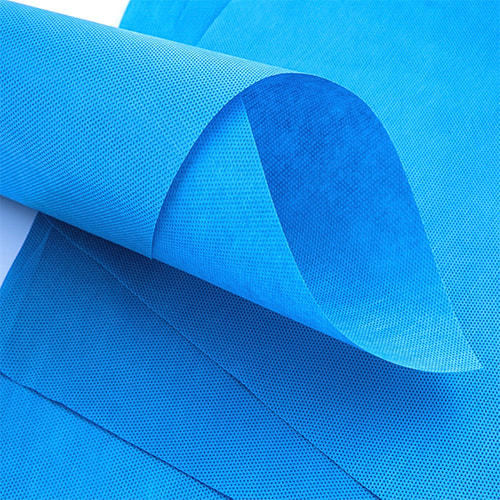

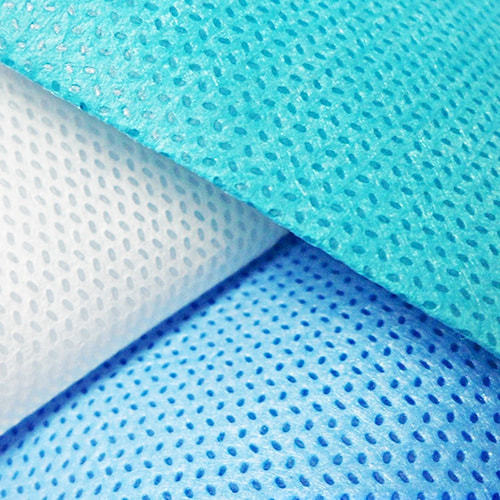

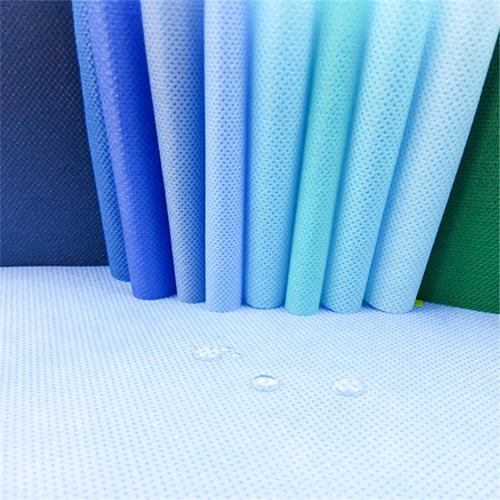

PP (polypropylene) spunbond nonwoven fabric is a type of nonwoven material that is manufactured using a process called spunbonding. It is made from continuous filaments of polypropylene that are extruded and then laid down in a random pattern to form a web of fibers. These fibers are then bonded together mechanically, thermally, or through the use of chemical additives, without the need for weaving or knitting.

Here are some key characteristics and uses of PP spunbond nonwoven fabric:

Lightweight and Breathable: PP spunbond nonwoven fabric is typically lightweight, which allows for good breathability. It has a porous structure that permits the passage of air and moisture, making it comfortable to wear or use in applications where breathability is important.

Strength and Durability: Despite its lightweight nature, PP spunbond nonwoven fabric offers good strength and durability. The fibers are tightly bonded, providing resistance to tearing and puncturing. This makes it suitable for applications that require a strong and robust material.

Hydrophobic and Moisture Resistance: Polypropylene has inherent hydrophobic properties, meaning it repels water and resists moisture absorption. PP spunbond nonwoven fabric maintains this characteristic, making it suitable for use in applications that require moisture resistance, such as protective clothing, agriculture, or packaging.

Chemical Resistance: PP spunbond nonwoven fabric exhibits good resistance to various chemicals, oils, and solvents. This property allows it to withstand exposure to different substances, making it suitable for industrial and agricultural applications.

PP spunbond nonwoven fabric offers a balance of cost, performance, and versatility, making it a widely used material in various industries. Its lightweight nature, breathability, and resistance to moisture and chemicals contribute to its popularity in many applications.

If you are interested in our Spunbond non woven fabric or have any questions, please consult us.